“AMPI was vital in directly funding the project. It’s very hard to get funding for research around building machinery as it’s capital intensive. So AMPI is quite unique in being able to make these things happen”

Professor Robert Kay

The University of Manchester and the University of Leeds were working independently on robotics, 3D printing and advanced manufacturing projects, and both shared a vision to develop next-generation manufacturing technologies in these areas. There was obvious complementary experience that could be deployed towards solving complex machinery problems. But without a mechanism to bring them together, there was no route to realising this benefit, or even defining what was possible.

When AMPI began, the two Universities, as founding partners, took part in collaborative forums set up to explore industry needs and solutions. Those brought together Robert Kay and Andrew Weightman, respectively professors of Advanced Manufacturing at Leeds and Medical Mechatronics at Manchester.

“We’d never met before, despite working in similar areas, but once we got together we did a lot of brainstorming and worked out how we could link our work for the benefit of UK machinery.”

Professor Robert Kay

This led to a project that merged the University of Manchester’s expertise in soft robotics with the University of Leeds’ capabilities in 3D printing and automated assembly.

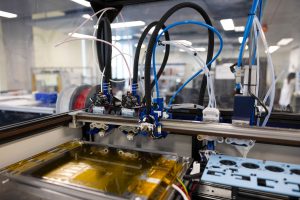

The collaboration has since delivered a novel machine concept capable of integrating additive and subtractive manufacturing techniques – the Automated Robot Manufacturing System (ARMS), pictured left – thanks to innovative tool head changes, multi-material manufacturing capabilities and agile pick and place grippers.

AMPI provided the framework for collaboration between the universities and the Technology Forums hosted by AMPI facilitated knowledge sharing between academia and industry throughout the project. This created a collaborative ecosystem that encouraged cross-learning. Without AMPI it is unlikely that the two universities would have connected and collaborated in such depth.

“AMPI has been essential in breaking down silos and fostering collaboration between our institutions. By linking our research efforts, we’ve unlocked new possibilities for the future of UK manufacturing.”

Professor Robert Kay

It is notoriously difficult for universities to work together on developing advanced machinery due to the competitive nature of R&D grant funding and the rules around funding allocation. AMPI’s autonomy allows it to direct its funding towards collaborations that will deliver the most impact, rather than based on one-size-fits-all assessment metrics.

Innovation for Machinery (I4M) is a funding scheme that provides SME businesses in Greater Manchester and West Yorkshire with access to advanced machinery expertise to accelerate the development of the next generation of machinery and create new jobs and growth in this sector.

Find out if you are elidgble for funding