Craftsman Tools is a UK-based, family-run precision engineering company. Their work includes the design and manufacture of fixture devices that locate and clamp components in position during machining, even under high machining forces, to ensure a high precision finish. One such product range – collets – are used during the precision grinding of internal combustion engine parts such as crank and camshafts and have long been in demand from the automotive manufacturing industry.

As the automotive industry transitions to EVs, Craftsman Tools has started work on a new concept collet design to tap into this lucrative market.

EVs have a particularly large demand for splined components. These interlock, like bike gears, allowing rotational force (torque) to be transferred from one to another. This is fundamental to force transfer in EVs and can be very different to those used in combustion engines.

“Our existing equipment is designed to hold round smooth components in place. Gripping splined components, accurately, presents different technical challenges.”

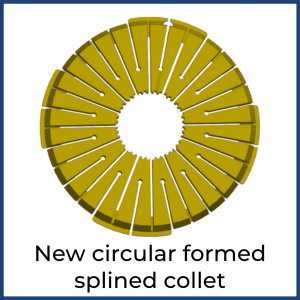

To address the problem, Craftsman Tools have developed a new circular formed splined collet, which has mating splines that can be integrated into their existing collet design, and can be manufactured to suit a large diameter range of splined components.

However, there was some uncertainty around if, and how, the splines may react or deform under forces experienced during manufacturing. They were confident that their tools could be adapted to hold splined components but couldn’t say what force they would withstand with complete certainty, and didn’t have a reliable method to test and validate them.

To address these challenges, Craftsman Tools worked with experts at the University of Huddersfield, through I4M, a programme funded by the UK Research and Innovation’s Strength in Places Fund and administered by the National Physical Laboratory (NPL).

Huddersfield University developed a specialised testing rig to simulate typical conditions and forces of spline machining. Craftsman secured a test splined part into their workholding system, and the rig applied various forces to the part to replicate different machining conditions, whilst measuring how the teeth were responding under that force.

Initial testing of the collet, clamping splined components, is underway with positive results. The collet is proving that it can withstand forces, typical during machining processes with minimal slippage or deformation. This has given Craftsman Tools insight and confidence that the collet can be used in applications it was designed for.

Additionally, the I4M project developed a way to measure the splines, that could be replicated at Craftsman by adapting its existing measurement equipment. That gave them the in-house tools to measure the alignment and structural integrity of new splined workholding systems, without the need for costly new measurement equipment.

“The teams at Huddersfield University and NPL made for a great partnership. They understand our products, and the underlying engineering, and can find solutions quickly.”

Thanks to the I4M project, Craftsman Tools now has a validated holding product they can offer customers within the EV market. It can certify that the product can withstand the torque and force levels requested by EV manufacturers, and provide data-backed safety limits, giving customers complete confidence in the collet system.

This will allow Craftsman Tools to deliver against the growing number of enquiries from EV component manufacturing customers, which until now, have been out of reach, with potential sales be in the region of £150,000 in the first 12 months. Ultimately it will help them to expand into the rapidly growing global EV market, as the combustion engine market declines.

The acquired measurement data also offers insight into the critical design features for holding splined components, which can help them reduce costs to allow for further margins.

Craftsman Tools have now joined the Advanced Machinery and Productivity Institute (AMPI) consortium, allowing them access to our network of machinery manufacturing expertise and secure funding for future projects through the UKRI’s Strength in Places Fund.

“Workholding systems for splined components could prove a valuable future line of business, especially as our automotive customers scale up EV production. But without the I4M support, we probably wouldn’t have committed to the project. Doing it alone would have been difficult, creating distractions and disrupting our core business.”

Tim Thorburn, Managing Director, Craftsman Tools

The funding scheme provides SME businesses in Greater Manchester and West Yorkshire with access to advanced machinery expertise to accelerate the development of the next generation of machinery and create new jobs and growth in this sector.

Find out if you are elidgble for funding